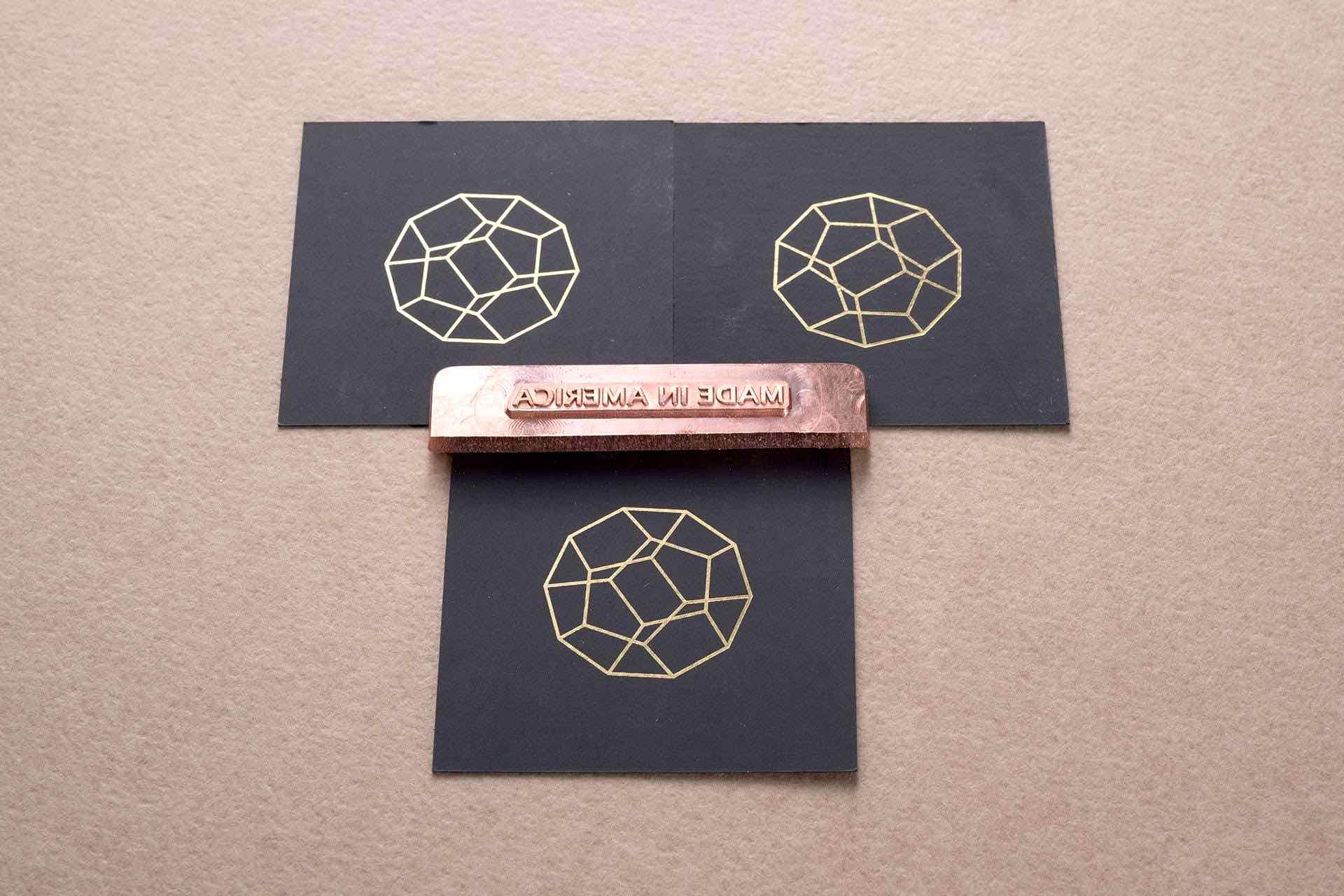

Here’s how the foil stamping process works:

- The image to be stamped is made into a stamping die, typically made of magnesium or copper for flat stamping, brass for multi-level, sculptured or combination dies

- The die is mounted in a press and heated to 170 to 240 degrees F

- Foil is pulled across the heated surface of the die

- The paper is pressed to the foil, transferring the pigment from the sheet to the printed piece

There are several variations of foil stamping, some of which include:

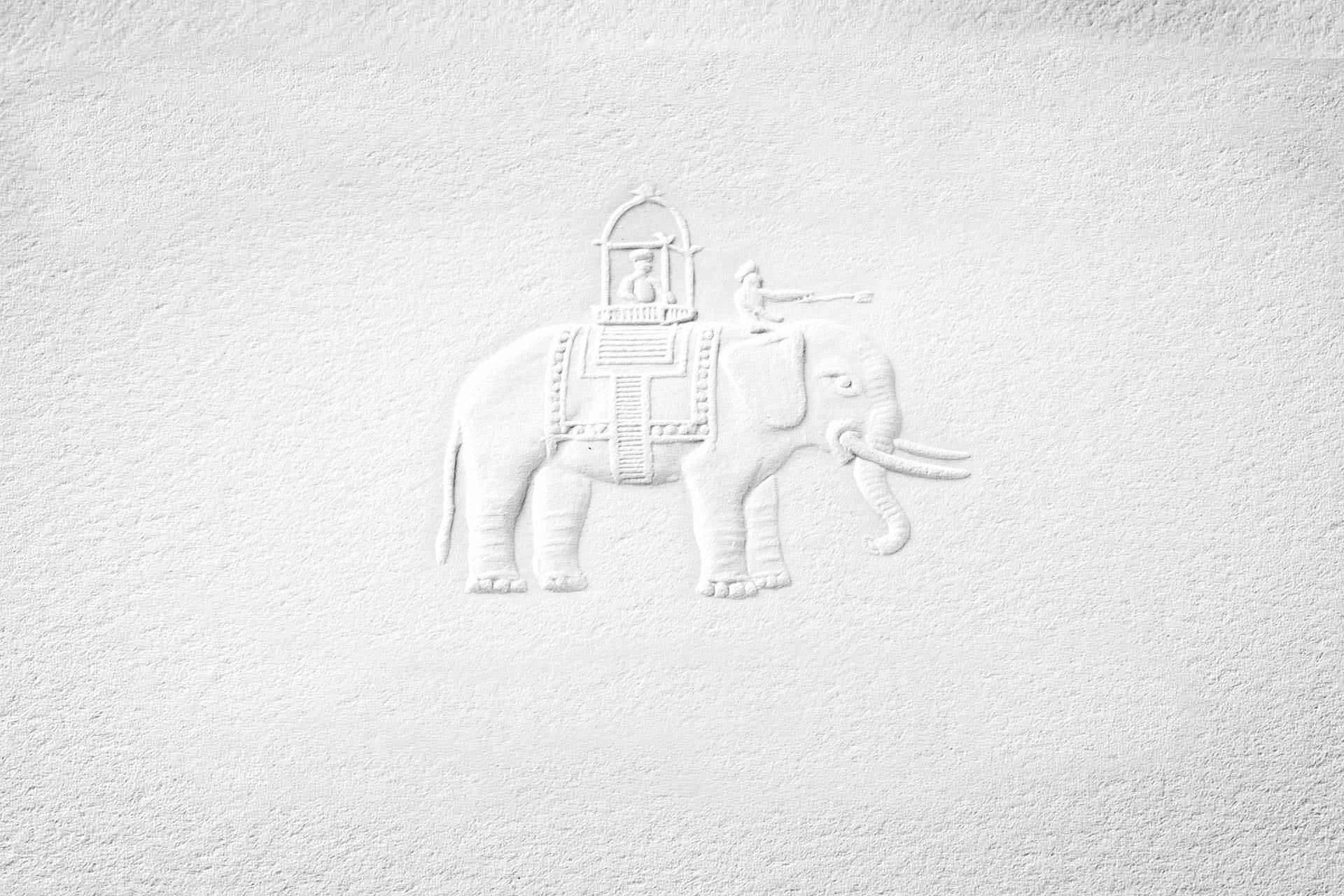

- Foil embossing, where the image is both foiled and embossed.

- Foil embossing can be produced in two separate press passes using two separate dies, or in one pass using a combination die. The embossing can be single level, multiple level or sculptured.

When we mention foil stamping, most people think of shiny metallic foils like gold and silver. Today foil comes in many color and finish variations of foil, shiny metallic foils, and pigment colors in a variety of finishes including gloss, semi-gloss, and matte, giving printers and customers endless options.